|

|

|

|

DMC = Disassembled Motor Car

Quote of the Week:

"You sure you want to keep that Volvo engine? The guys in the shop can

probably whip up a 1500HP Hemi for ya'."

-Dad

Home

Prev Week 21 Next

March 11-17, 2000

| I noticed a -huge- restriction on the turbo intake manifold where it

mates with the stock throttle body. I redesigned the head end a bit.

The details and photos are below... My dad's company (Hussey Copper) has a marine division, which for some reason has gotten into drag racing. They now are a top manufacturer of copper gaskets for the race trade, and my dad is offering their services for a port & polish job! I had considered Extrude-Hone, but to do the int/exh manifolds and the heads was $1800. That's a sizable chunk of change. Therefore, having a professional race team redo those for free seemed to be a much better option. However, to do so would mean delaying finishing the engine by a month or two at least, and quite possibly a much longer period of time. That depressed me a bit. I was really getting far along, and then... a huge delay. I have the potential to build one of the hottest PRV's in the country (I hope), but should I do so when it would hit me with such a morale killer? There a line in a Phish song that struck me at this point: "A week is a month, and an hour's a day, when your reaching just pushes it further away". Sage advice. I've run into that trap before. You have to set a goal of what you want the car to be when it's done and try to stick to it. Every time you try to do a bit more, the goal moves further out of reach. It's better to accomplish your original goals first, then set additional ones. To do otherwise is just baiting yourself with a carrot and stick. I'll send my spare heads and intake down to be machined, and put them on at a later date. A little more work, true, but on a project of this size & scope, keeping my energy level and spirits high is of crucial importance. With that in mind, I went back to work on the engine yesterday. The intake manifold is in place, the new distributor, and all of the water piping. I started in on the exhaust & turbos next, and hope to have the engine assembled by the end of the week. My 30th birthday is on Wednesday, so I probably won't be working that night. But now that I'm "old", I should act responsibly, correct? I'm starting my new responsibility with going to a Toga party at my old Penn State fraternity this Saturday, so putting the engine in that weekend is out of the question. =) Last week was a big one financially -- I spent more than I did on the car. For those of you who are following my progress and hoping to find a cheap D, you will note that at this point I have passed the cost of purchasing a decent running car. Remember, I'm doing this for the challenge, for the fun, and for the love of the marque. The money is secondary to me, and I would NOT recommend buying a car in such poor shape. |

|||||||||||||||||||||

|

Spare heads and intake are on their

way to being hot pieces of machinery.

Someday. |

||||||||||||||||||||

|

Twin Turbo Mods:

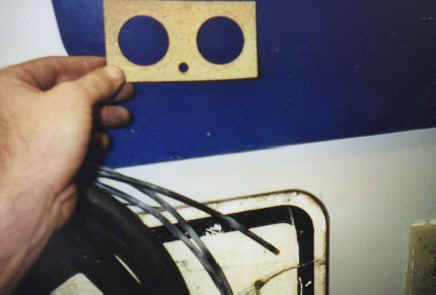

Okay... now looking at this rather fuzzy pic, you can still see that the size difference between the original throttle body and the turbo kit's mount is substantial. Quite a big restriction. It's amplified by the enlarged area on the throttle body where the brass fittings on the old rams horns fit, PLUS the O-rings. Turbulence and restriction at this point is HUGE. |

||||||||||||||||||||

|

I started by using the supplied gasket, and pressing the rams horns down firmly on the gasket, marking it with the size it should be. I then cut out the gasket to match. | ||||||||||||||||||||

|

I traced the gasket onto the supplied mount, and then checked against the original. The tracing was a bit small, so I readjusted my markings, and began to die-grind the restriction away. | ||||||||||||||||||||

|

Now, if you've ever used a die grinder on aluminum, it's something like taking a file to a block of Velveeta. It immediately clogs the bit badly. I had to alternate between grinding the aluminum, and grinding the aluminum off of the bit with a bench grinder, and then grinding the aluminum off of the bench grinder. What a chore... | ||||||||||||||||||||

|

But the end result was worth it. It matched the

size of the rams horns almost exactly.

Check out the difference in size against the pictures above. |

||||||||||||||||||||

|

Now remember that I mentioned that the rams horns had a

brass sleeve to fit into the throttle body with an O-ring seal? That area

would still pose a restriction unless it was filled in. I considered

using a filler like JB Weld, but was concerned any pieces cracked off

would end up munching the turbos or the engine. A piece of

1-7/8" exhaust pipe was almost perfect to make a new 'sleeve'.

It required very slight grinding to fit snugly.

|

||||||||||||||||||||

|

I then used an exhaust tubing cutter to cut two 'rings' to fit into the throttle body... | ||||||||||||||||||||

|

The original O-rings fit back in place to seal and secure the metal spacer rings. It isn't quite perfect, but it's close. The photo amplifies the edge a bit. It actually has a nice taper between the pipe ring and the throttle body. | ||||||||||||||||||||

|

The modifications are complete. With the modified

supplied adapter in place, you can run your finger up through the assembly

and barely feel the edges. This is compared to the approximate

1/4" gap you could feel before.

Should be worth a few more ponies, to be sure. |

||||||||||||||||||||

| Costs for Week 21: | |||||||||||||||||||||

|

|||||||||||||||||||||

Copyright ©

ProjectVixen.com. All rights reserved.

Opinions expressed in posts reflect the views of their respective authors.

DMCForum Mailing List Archive

DMCNews Mailing List Archive

DMC-UK Mailing List Archive

This site contains affiliate links for which we may be compensated